<br>

##Composite making.

###What it is.

###Compression and extension.

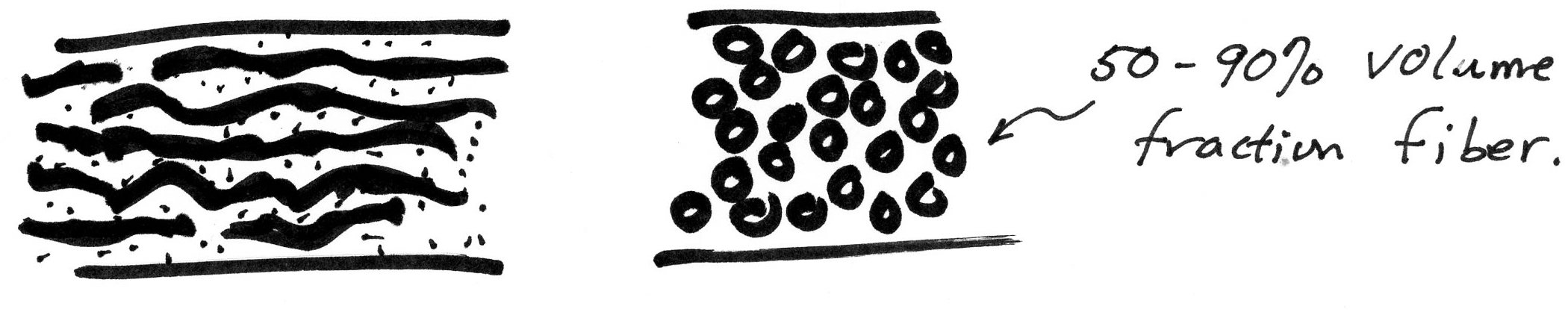

A composite material usually combines one component that is strong in compression (the matrix) with a second component

(the fiber) that is strong in extension. The resulting material is stronger than either component alone.

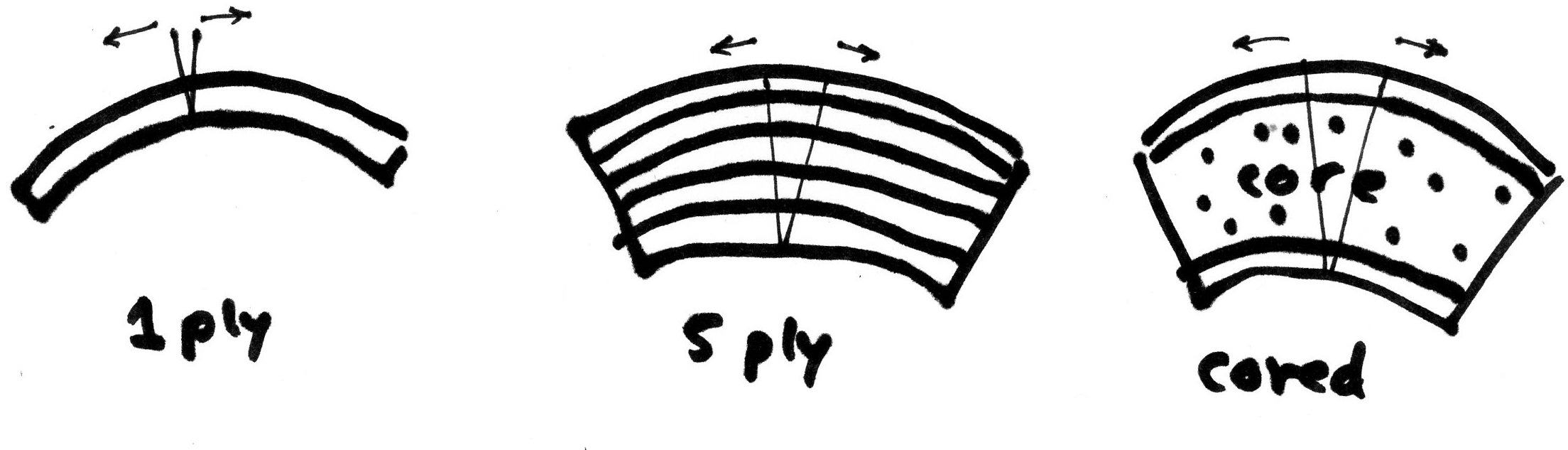

See below what happens to stiffness as you go from one layer (floppy) to five (much stiffer) to a cored arrangement (almost as stiff as five.)

###How it is made.

###Modelling and exporting.

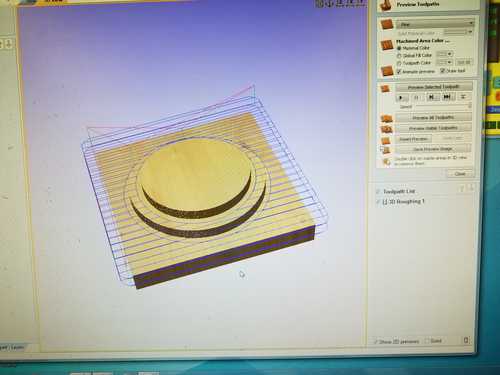

Model a 3D object in Fusion. [(file here)](./Composite01.v2.f3d) and export an [STL file.](./Body4.stl)

###Process for toolpath creation.

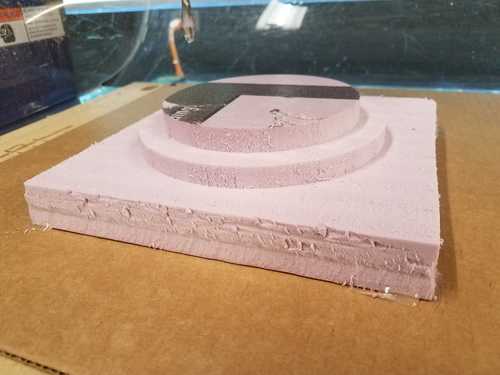

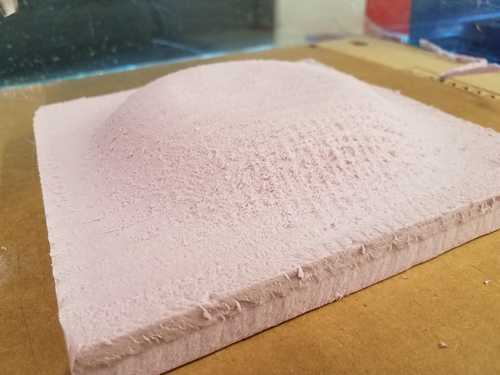

Preview and actual rough cut in foam of bowl shape.

Procedure to insert stl into V-carve program to create toolpath.

- Open V-carve.

- New file.

- Set up material, in inches or mm.

- Import 3D

- Set scale

- Adjust position of base plane in model.

- Set up roughing toolpath.

- Adjust model height in material.

- Select tool. Choose stepover.

- Use preview to check, and adjust cutting area as needed.

- Set up finishing toolpath.

- Select tool. Maybe reduce stepover.

= Check preview and adjust if needed.

- Save toolpaths.

- Mount foam and zero the cutter in x,y,and z.

- Run toolpaths.

###After finishing cuts in foam.

###Composite layup procedure.

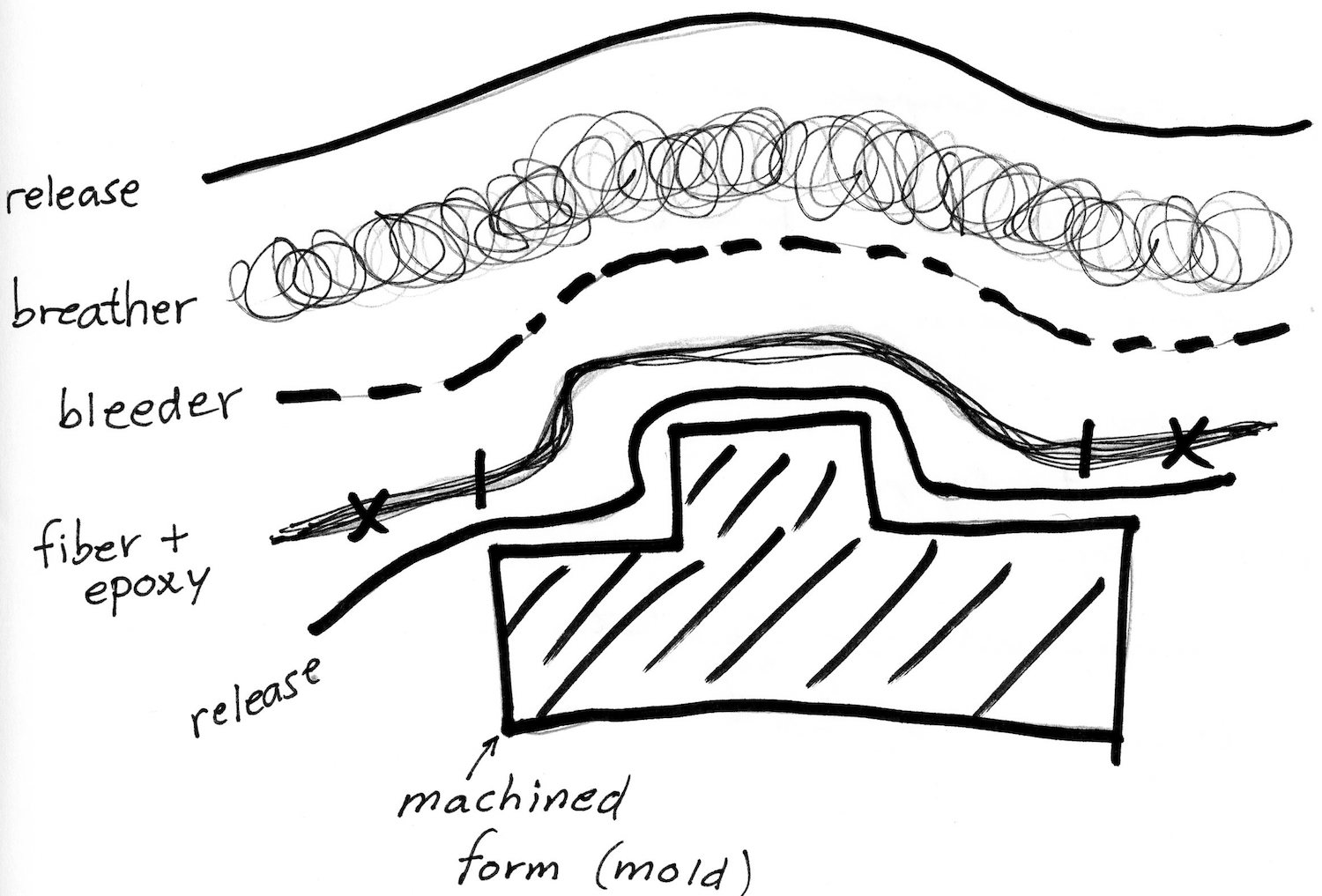

Saturate fiber layers with epoxy and lay up on mold, with release layer underneath.

Add bleeder and breather.

Insert in bag, pull vacuum and seal.

Cure overnight, pull out, separate layers, trim. Finished!